SB Screeding

07950 714111

Floor Preparation.

At SB Screeding, we prioritise attentive floor preparation to ensure the successful installation of liquid screed. Here's how we prepare your floor:

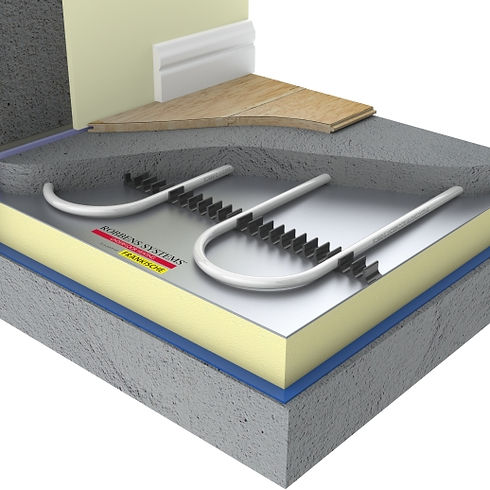

Slab Prep and Insulation:

Before proceeding with insulation, we thoroughly clear the floor slab of any debris, high spots, or lumps. This initial step is crucial to ensure a stable foundation and prevent potential issues with the final screed finish.

Polythene Membrane Application:

Following base preparation, we lay a thin layer of plastic sheeting over the insulation. This sheeting extends up the walls, creating a watertight seal that prevents leaks and ensures optimal protection for your flooring system.

Expansion Upstands:

We provide insulation upstands along all perimeters, using a 5 or 10mm polyethylene foam expansion strip. This strip extends to the full depth of the screed, sealing junctions with walls, corners, and door thresholds to eliminate air pockets or voids.

Pipework installation:

Our team lays the underfloor heating system pipework as required, ensuring it is securely fixed to the floor. Proper fixation prevents issues such as lifting or floating, ensuring the integrity and longevity of your underfloor heating system.

By professionally following these preparation steps, we guarantee a solid foundation for your liquid screed installation. This meticulous approach ensures optimal performance and durability of your flooring system for years to come.

Transform your flooring with our sustainable liquid screeding solutions. Contact us today to discuss your project and receive a free quote.

Floor Preparation